| |

|

NECO

IS

PUMPED

UP

FOR

SERVICE

Field Service

|

|

Count on NECO to provide the services necessary to keep your pump packages running smoothly, and in top notch condition. Skilled technicians make up NECO's Field Service team and offer you expert on-site installation servicing for pumping system packages and Engineered Kits.

|

|

Plus, annual preventive maintenance plans and emergency servicing calls are always available to NECO Systems, Inc. customers.

|

|

|

COMMITTED SERVICE

TOWARD

KEEPING

YOUR

SYSTEM

RUNNING:

Qualified

NECO

field

service

personnel

are

always

available

to

perform

the

following

services

and

repairs:

-

Pump

rebuilds

-

Replacement

of

bearings

and

seals

-

Pump/Motor

Replacement

–

Install,

re-plumb,

and

fully

test

-

PRV's

–

Rebuild

and

adjustment

of

Pressure

Regulating

Valves

-

Control

Adjustments

–

Readjustment

of

pressure,

flow

and

temperature

settings

-

Upgrades

–

Pumps

&

controls,

component

replacement

-

Annual

Preventive

Maintenance

–

For

Boosters,

Circulating

Systems

&

Heat

Transfer

Systems

(Service

includes:

checking

voltage,

current

draw,

pump

alignment,

control

adjustments

&

gauges)

With

a

NECO

Preventive

Maintenance

service contract,

should

any

new

or

rebuilt

parts

be

required

following

a

service

call

and

inspection,

a

discount

on

parts

and

labor

will

apply.

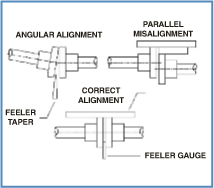

Laser Alignments

In

skid-mounted

pumping

systems,

proper

alignment

is

critical

to

achieving

a

long

useful

service

life

and

leak-free

operation.

That's

why

NECO

now

uses

the

very

latest

laser

alignment

technology

to

insure

correct

tolerances

are

achieved

and

maximum

pump

life

is

realized.

Misalignment

will

cause

many

problems,

among

them:

-

Increased

forces

on

shaft,

bearings,

and

couplings

-

causing

premature

wear

and

pump

failure

-

Increased

friction

–

creating

heat,

efficiency

loss

and

extra

operating

expense

-

Soft

foot

–

causing

vibration

and

failure

|

|

|

|

ACCEPTABLE

PUMP

ALIGNMENT

TOLERANCES

ARE:

|

3600

RPM |

1800

RPM

�

� |

3600

RPM |

|

Parallel

alignment

�

� |

002" |

.004" |

|

Angular |

.004" |

.006" |

|

Traditional

pump

alignment

methods (without laser alignment)

are

not

accurate

enough

to

achieve

these

stated

tolerances,

regardless

of

the

technician's

skill

level.

At

NECO,

all

frame-mounted

pump

packages

are

aligned

at

the

factory

prior

to

shipment.

However,

as

all

base

plates

are

flexible

to

some

extent,

they

should

not

be

relied

upon

to

maintain

their

factory

alignment.

Shipping

and

installation

can

often

cause

pumps

to

be

misaligned.

Realignment

may

be

necessary:

-

After

the

unit

has

been

set

level

on

the

foundation

-

After

the

grout

has

been

set

and

the

foundation

bolts

tightened

-

After

the

pipes

have

been

connected

and

insulated

-

Accurate

laser alignment

is

absolutely

essential

and

as

part

of

NECO's

Start

Up

service,alignment

is

always

rechecked

in

the

field.

*

Proper

mechanical

operation

of

the

equipment

cannot

be

guaranteed

unless

factory

alignment

has

been

maintained

in

the

field.

Any

realignment,

if

necessary,

should

be

made

by

moving

or

shimming

the

motor.

The

flexible

coupling

compensates

for

temperatures

and

permits

end

movement

of

the

shafts

without

them

interfering

with

each

other;

it

will

not

compensate

for

misalignment.

Faulty

alignment

will

result

in

noisy

pump

operation,

reduced

bearing

life,

excessive

coupling

wear

and

wasted

power.

|

NECO Systems Inc. - Engineered Pumping Solutions

458 East King Rd., Malvern, Pa 19355

Tel: 215-721-2200 Fax: 610-648-0880

|

|